BENEFITS OF INCORPORATING KIT BUILDING INTO AN ELECTRONICS OR MECHATRONICS COURSE:

Whether or not to incorporate kits into an electronics program seems to be a point of contention

amongst electronics instructors. I have heard negative comments such as, “Kits are a waste of

time. The students make a bunch of mistakes trying to put them together, then get frustrated

because they don’t work!”

Personally, I am a great believer in building electronics kits. If

administered effectively, I believe the experience can prove invaluable in providing a hands-on,

“under the hood” experience that is not possible with just breadboarding. If done correctly, kit

building involves both the cognitive and kinesthetic (psychomotor) domains, thus enhancing the

learning process. Assembling, testing and, if necessary, troubleshooting electronic kits might

well be the closest experience a student could have to a day on the job as an electronics or

mechatronics technician.

The New Student’s First Kit Building Experience:

There are many maker/hobbyist DIY (Do it Yourself) electronic kits on the market that are

inexpensive and fun to build. For example, cobbling together a kit that repels mosquitos with

an ultrasonic wave could provide valuable soldering practice and certainly have a practical

application on the back patio.

In fact, building any form of electronic kit could be a positive

experience for the new student, generating enthusiasm and instilling confidence.

A kit such as the mosquito deterrent circuit could possibly work as an introductory build

experience for first term students.

But to make the experience worthwhile in a school laboratory

environment, the instructor must be creative and fill in some gaps, identifying additional

procedural steps that could be performed during the build process. These steps are necessary

to enhance the educational experience. Simply turning students loose with a "Go to it; have

fun!" attitude could end in frustration and disaster. It is human nature to cut corners, not read

instructions, and rush through a process. Left on their own, students might try to assemble a

small kit in one class period, as if the goal were to finish the task as quickly as possible. These

are behaviors we absolutely do not want to instill into future electronics and mechatronics

technicians!

To keep students motivated and engaged, the instructor might consider:

- Dividing the build process into stages, with a specific milestone after each stage. For

example, the students could be expected to identify each resistor contained in a kit by its

color code. They would then be required to measure the ohmic value of each resistor

and determine if it is within tolerance.

- Delivering a brief explanation before embarking on each assembly stage, specifying

educational objectives to be met.

- Where applicable, requiring teacher sign off after completion of a stage. The sign off

could require a demonstration of a competency: "Show me how you measured the

voltage at point B."

- Provide an occasional "Show and tell” moment." While students might not be at a point

in their training where they use an oscilloscope, the instructor could connect the scope to

a student's completed circuit board and show them the 25KHz waveform that annoys the

mosquitos.

While this might seem trivial to the seasoned technician, it could be an

inspirational moment for the new student!

The PRESSON Innovative Approach to Kit Building:

As discussed above, building a DIY kit during an electronics course program can have its

benefits. But PRESSON Circuit Modules, Inc. takes kit building to a new level. Assembly and

testing of PRESSON circuit module kits is an integral process within the company’s PDF

courseware (offered free with each module). Each PRESSON kit becomes the focal point of:

- A very detailed, step-by-step assembly procedure

- A step-by-step testing procedure

- One or more lab/theory lessons containing several experimental procedures involving

that module

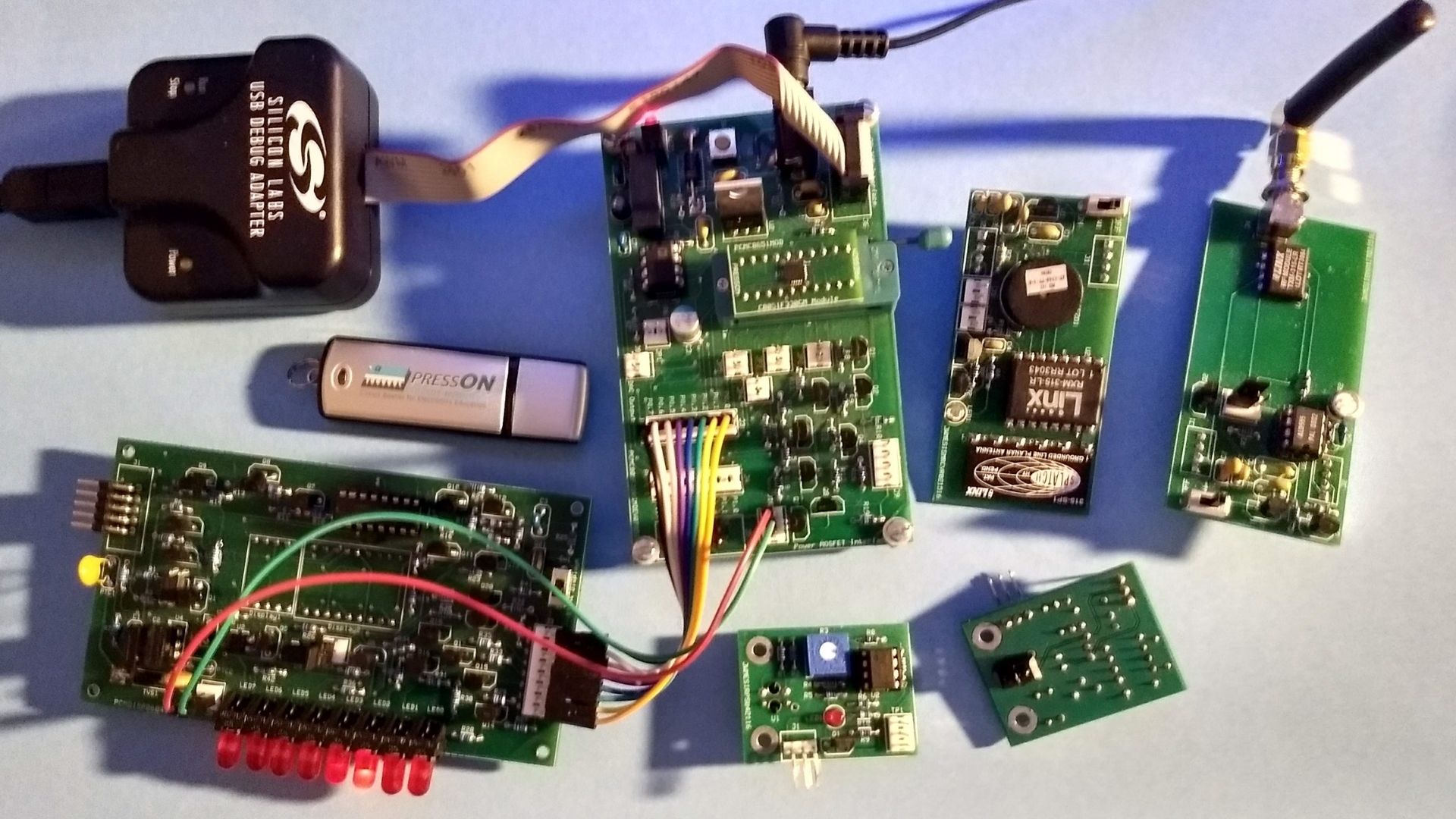

- Additional lab/theory lessons in which the module is interfaced with other PRESSON

modules and breadboarded circuitry

Click here to see an excerpt from a PRESSON assembly procedure.

Click here to see an excerpt from a PRESSON theory/lab procedure.

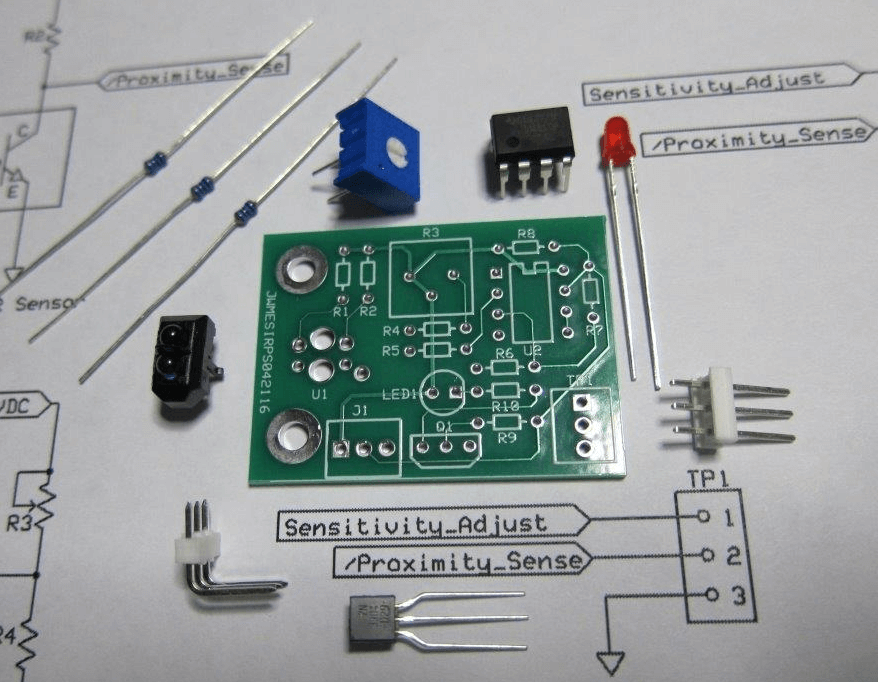

PRESSON kits comprise a family of circuit modules, designed primarily for use in the study of

industrial electronic control systems. Unlike many DIY kits, PRESSON modules are designed

for easy mounting onto grounded base plates and can function directly within an actual control

system. To support their use within an advanced student’s capstone project, or application

within an actual piece of machinery, PRESSON Circuit Modules, Inc. provides a thorough user’s

guide, or data manual for each circuit module. Each guide contains complete schematic

diagrams and a concise, but detailed theory of operation. PRESSON users’ guides and

courseware contain direct hyperlinks to manufacture’s datasheets for the sensors and

integrated circuits contained on the modules.

Click here to see a PRESSON user's guide.

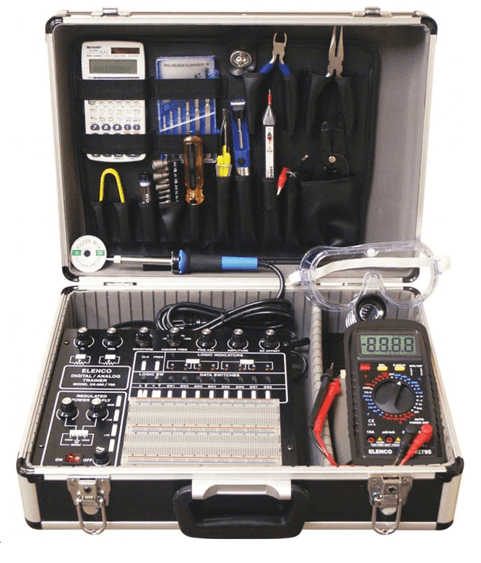

Finally, PRESSON breadboard circuit modules are ideal for use with portable trainers, such as

that shown below.

Assembled PRESSON breadboard modules can fit easily into the breadboard section of the

portable trainer shown above, while PRESSON freestanding modules can connect easily to

the DC power sources provided at the portable trainer console.

Click here to learn more about PRESSON kit options.

In closing, it should be stressed that PRESSON Circuit Modules and supporting courseware

could be used in a wide variety of educational and training application. While the kits and

courseware could become supplemental materials within a four-year electrical engineering

program, they could play a more dominant role in a shorter training program for electronics

or mechatronics technicians.

PRESSON courseware could also be easily consolidated into more compact nano degree or micro credential training programs for technicians and engineers already working in industry. For more details, please email us at [email protected].

Back To Blog