Mini-Capstone Projects in Electronics: Hands-On Learning That Builds Real-World Skills

Project-Based Learning (PBL) is a powerful method to engage students in exploring engineering careers, building their creative confidence, and developing practical technical skills. But for PBL to be truly effective—especially in electronics and mechatronics—it must go beyond abstract exploration and provide clear direction, structure, and tools.

At PressOn Circuit Modules (PCM), we believe that guided hands-on experiences can transform classroom learning into career-ready skill development. That’s why our mini-capstone projects are designed to challenge, support, and inspire students—without sending them into frustration or endless trial and error.

What Makes PCM Project-Based Learning Projects Different?

Feeling lost with different opportunities?

While traditional Project-Based Learning programs like those developed through Project Lead The Way (PLTW) encourage creativity and independent exploration, they often leave students without the structure or resources needed to succeed.

PCM mini-capstone projects are different:

🔹 Immersive and focused

🔹 Aligned with real-world engineering tasks

🔹 Built on progressive, hands-on learning

🔹 Structured for student success

Our approach is designed to replicate the kinds of tasks engineers and technicians perform in today’s automated and advanced manufacturing environments.

Example: Linear Actuator Control with Stepper Motor System

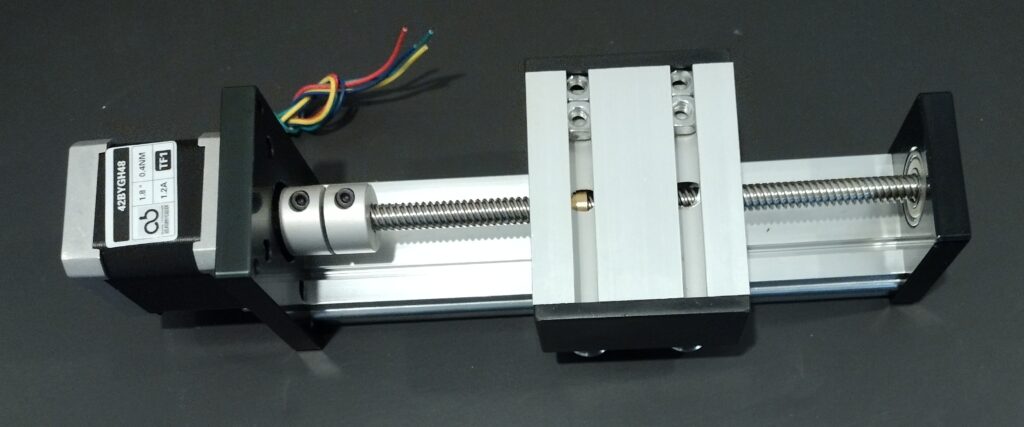

In one mini-capstone project, students explore the function of a Machifit stepper motor-based lead screw linear actuator—a widely used system in CNC machinery and gate control automation.

Project Objectives:

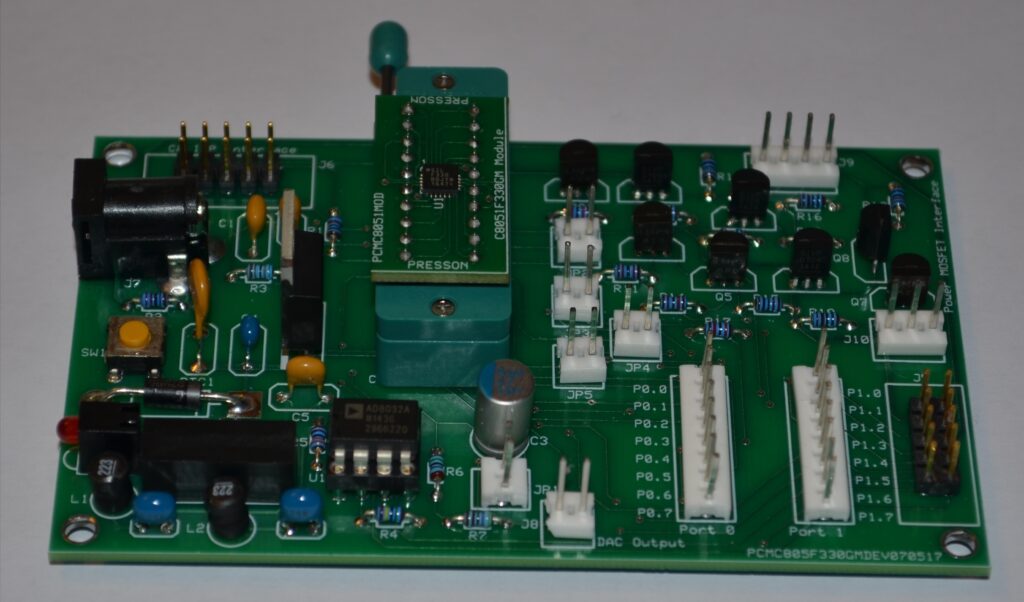

🔹 Program the PCM C51 Microcontroller Project Launcher to control motion profiles (speed, direction, distance).

🔹 Interface with the PCM Bipolar Stepper Motor Driver Module (currently in development).

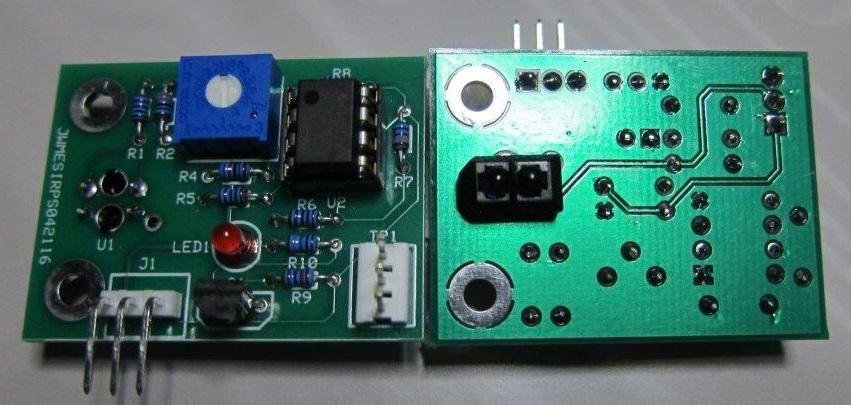

🔹 Integrate PCM Reflective Proximity Sensor Circuit Modules as non-contact limit switches for position feedback.

Students are expected to develop code that:

🔹 Executes precise forward/reverse motion profiles.

🔹 Monitors sensor signals in real time.

🔹 Safely powers down the motor at transit limits.

This structured yet challenging project closely simulates real industrial environments.

What Makes This Project-Based Learning Successful?

The linear actuator project is assigned only after students complete foundational coursework and labs in:

🔹 Microcontroller interfacing with electromechanical components

🔹 Stepper motor control using full-step, half-step, and wave drive techniques

🔹 IR sensing and motion detection circuits

By the time students begin the project, they’ve already built the technical foundation to succeed—minimizing frustration and maximizing learning.

This approach avoids overwhelming students with overly open-ended tasks. Instead of building an entire CNC machine from scratch, they gain hands-on experience with one of its most essential components—a linear actuator they’re likely to encounter in real jobs.

Outcome: From Lab to Industry

Through these mini-capstone experiences, students graduate with more than just knowledge—they gain:

🔹 Real-world electronics experience

🔹 Confidence in programming and control systems

🔹 Troubleshooting and system design skills

By mastering small, meaningful projects, learners build the confidence and technical expertise needed to work with complex industrial systems like CNC machines.

Want to Learn More about our Project-Based Learning?

Interested in bringing immersive, project-based electronics training to your school or institution? Get in touch here or reach out to us at:

📧 jim.maas@pressoncircuitmodules.com

Let’s transform how students learn electronics—together.