Our Tracks

TRACK 1 – SOON

Industrial Sensor Applications

Track 1 courses provide an overview of transducers and sensors commonly found in automated industrial control systems. These components serve key roles within closed-loop process control systems, monitoring system operating conditions while ensuring efficiency, accuracy, and safety. Learners will obtain basic theoretical knowledge of industrial transducers and sensors, reinforced by ample hands-on lab experience exploring their operation. Numerous hands-on project-based learning (PBL) opportunities are provided to enhance student knowledge of transducers and sensors.

By the end of Track 1, you will have a deep understanding of how these sensors work together to enable automation, improve system performance, and ensure safety across various industries.

Industrial Applications of Temperature Sensors

Delve into the study of the various temperature sensors found in automated manufacturing systems. Investigate various devices, including thermistors, resistive temperature detectors (RTDs), precision temperature detectors, and infrared (IR) thermal sensors. Learn how these devices improve precision, efficiency, reliability, and safety.

Industrial Applications of Optoelectronic Sensors

Discover how visible light sensors and infrared emitter/detector pairs are utilized within industrial process control systems. Investigate various optoelectronic devices, including ambient light sensors, optocouplers, photo interrupter modules, light barriers, and contactless proximity sensors. Survey industrial applications of lasers and ultrasonic devices.

Industrial Applications of Magnetic Sensors

Learn how various forms of magnetic and inductive sensors are utilized in modern industry, enabling accurate position sensing, proximity sensing, motor speed control, and AC current measurement. Investigated the operation of hall effect sensors, magnetometers, current transformers, and fluxgate sensors.

Industrial Applications of Vibration and Force Sensors

Understand how vibration, force, and pressure sensors improve safety and reliability within industrial machinery. Investigate the function of accelerometers and cantilever piezoelectric sensors in detecting position, impact, and vibration. Learn the function of pneumatic and hydraulic pressure sensors within industrial systems.

TRACK 2 – SOON

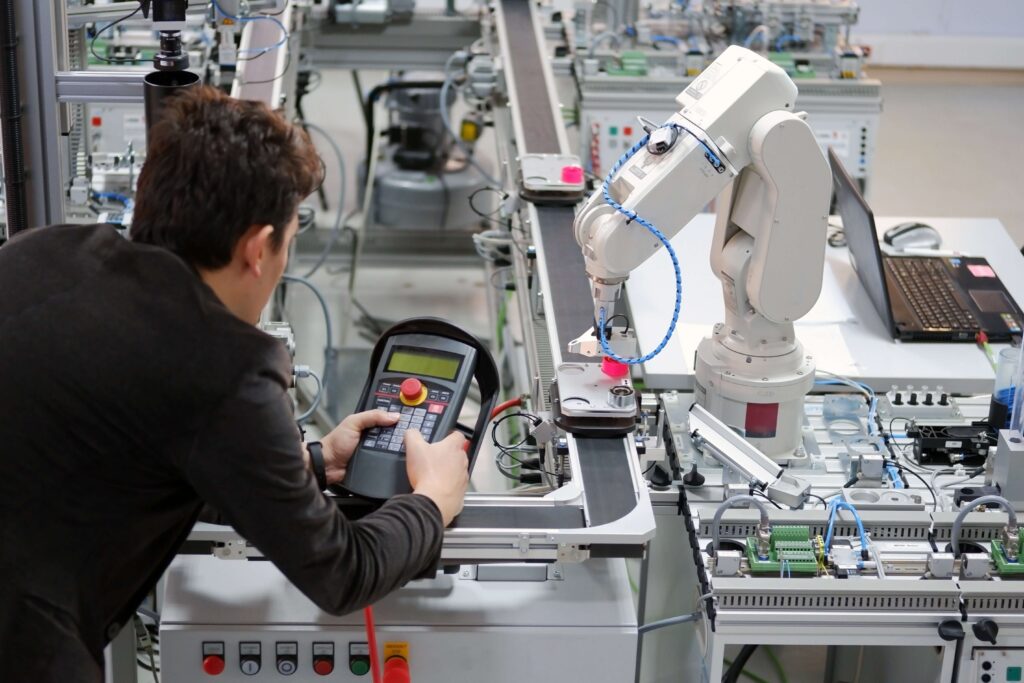

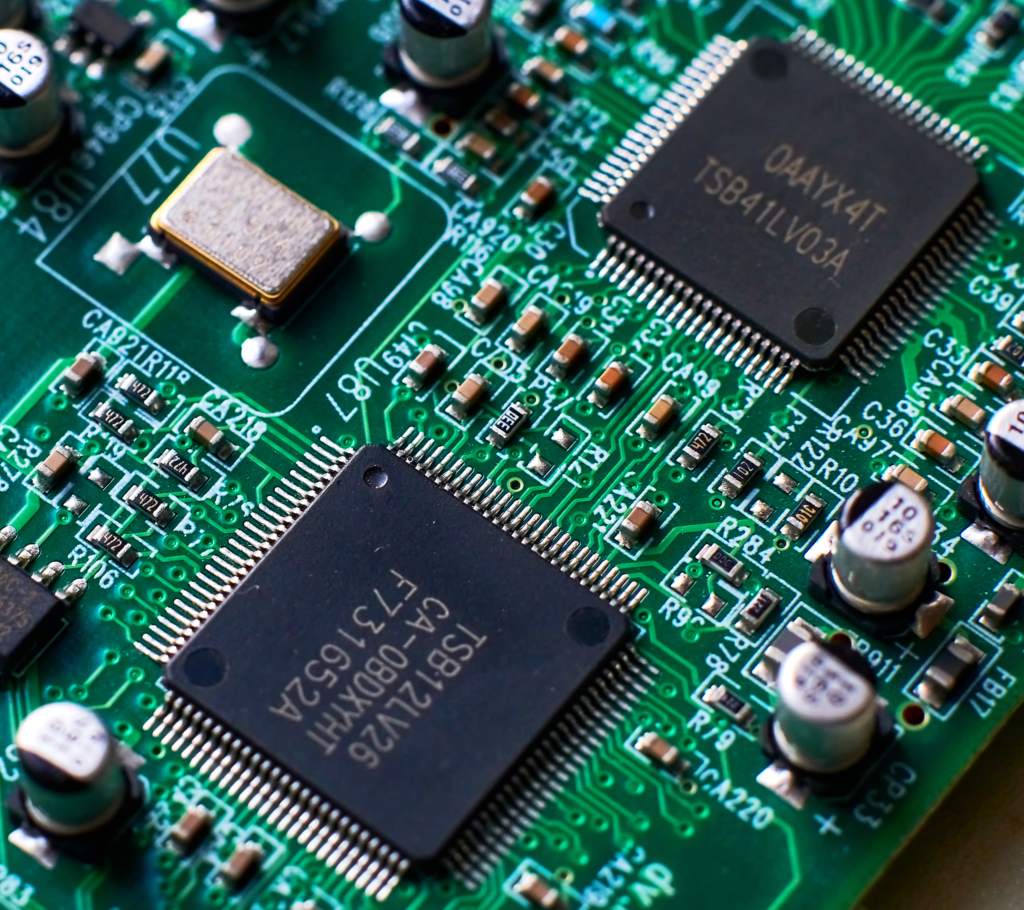

Industrial Applications of Microcontrollers

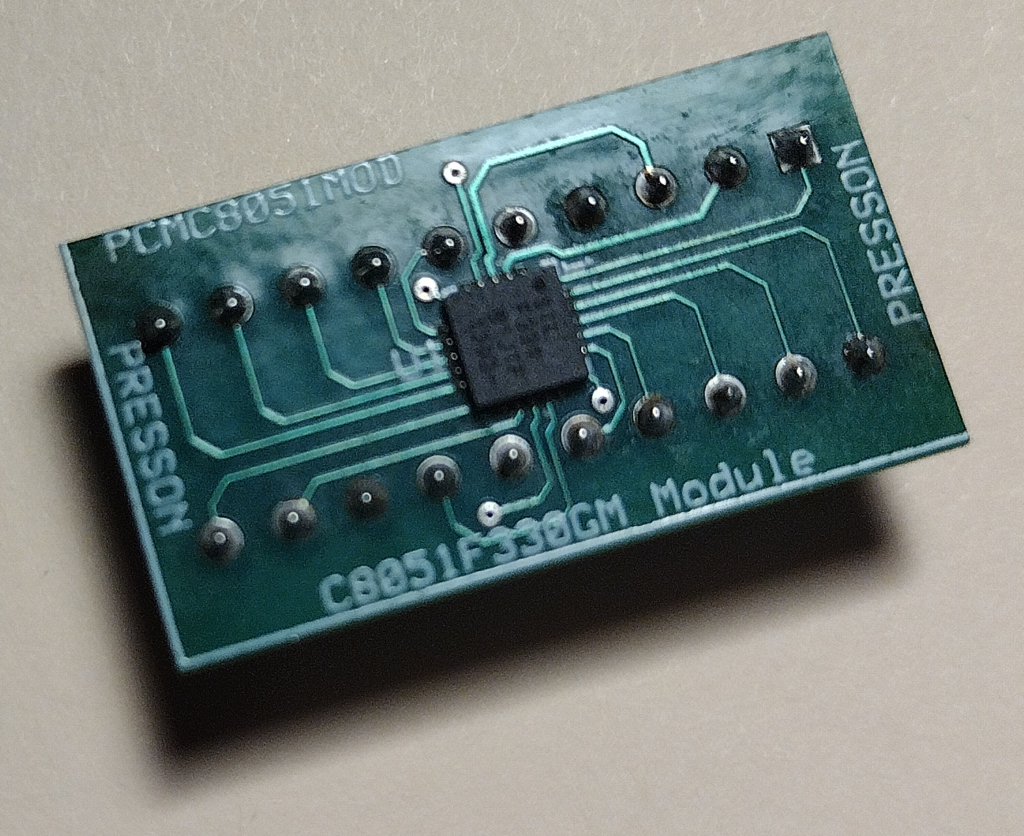

This track surveys several families of microcontrollers commonly found in automated industrial control systems. The track begins with a detailed study of eight-bit microcontroller architecture and programming, centered around the PRESSON C51 Microcontroller Project Launcher. The track continues with the study of other 8-bit MCUs then progresses into a survey of 16-bit microcontrollers and 32-bit devices based on ARM Cortex-M3 architecture. The track provides ample opportunity for hands-on mini-capstone PBL activities, allowing exploration of various methods of interfacing an MCU with peripheral devices and signal conditioning circuitry.

This track equips learners with the knowledge needed to select, configure, and program microcontrollers for a wide range of industrial applications.

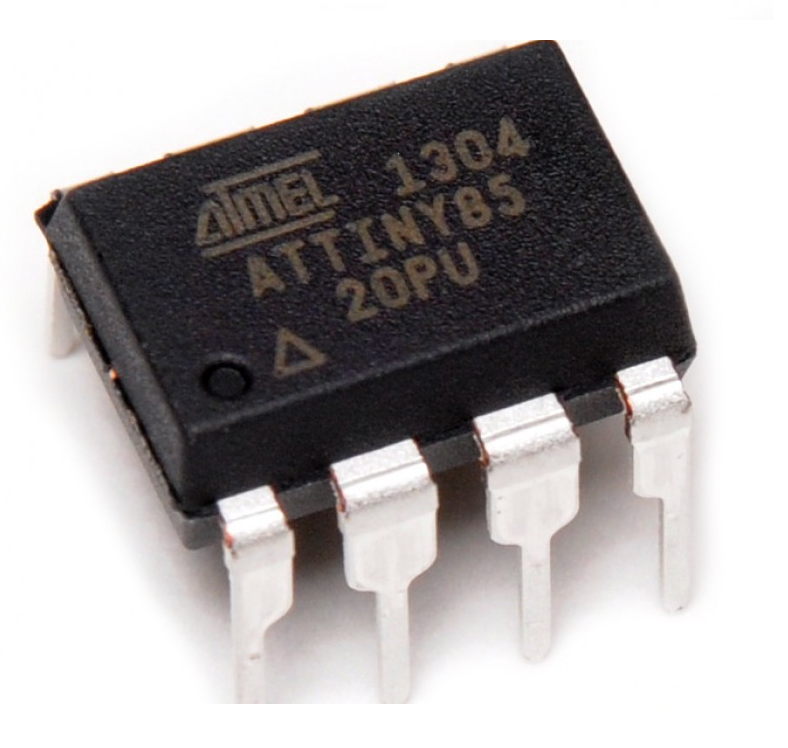

Introduction to Eight-Bit Microcontrollers

Learn the fundamentals of eight-bit microcontroller architecture and operation. Using the PRESSON C51 Microcontroller Project Launcher, learn the inner workings of the C51 core and obtain a foundational knowledge of assembly language programming. Learn to program MCU onboard peripherals through a series of challenging PBL-based lab activities.

Introduction to C Programming of Eight-Bit Microcontrollers

Acquire foundational skills in the C programming language, concentrating on the function of embedded controllers within industrial equipment. Using the PRESSON C51 Microcontroller Project Launcher, learn to program onboard peripherals and control operation of external devices using C language. Investigate C programming of other eight-bit microcontroller families.

Introduction to Sixteen-Bit Microcontrollers

Transition to the study of sixteen-bit MCUs by investigating the Texas Instruments (TI) MSP430 microcontroller family. Learn the structure and operation of the MSP430F2013IPWR MCU through a series of C language programming exercises. Engage in a PBL activity implementing that device in a closed-loop control system.

Introduction to Thirty-Two-Bit Microcontrollers

Learn the structure and operation of the ARM Cortex M3 thirty-two bit core, which is widely used in the design of advanced forms of MCUs. Survey the many applications of thirty-two bit MCUs, including automotive control systems, robotics, the internet of things (IoT), medical equipment, and consumer electronics. Develop a mini-capstone project using the Silicon Labs Pearl Gecko PG12 Starter Kit.

TRACK 3 – SOON

Industrial Applications of Electromechanical Devices

Learn about various types of electromechanical devices found in automated industrial equipment, beginning with basic manually operated switches, then proceeding to more complex electromechanical actuators, including solenoids and relays. Perform a series of theory/lab exercises exploring methods of safely connecting electromechanical devices to MCUs. Survey several forms of motor, include single-phase and three-phase AC motors, DC permanent magnet (PM) motors, servo motors, and stepper motors. Learn about various types of motor drive, including direct, gearhead, belt, and lead screw. Engage in challenging PBL activities involving microcontrollers, sensors, interface circuitry and motors.

Through this track, students will gain a solid understanding of how electromechanical devices operate and how they are applied in real-world industrial settings.

Introduction to Electromechanical Actuators

Survey the basic switch configurations (SPST, SPDT), and DPDT) and learn how they are used in manual and relay switching circuitry. Learn the structure and operation of DC relays, AC relays, and contactors. Design basic relay circuitry using ladder diagrams. Investigate the structure and operation of linear and rotary solenoids. Engage in PBL activities involving MCUs, relays, solenoids, and sensors.

Introduction to AC Motors

Delve into the study of motors by first learning the relationships of key motor operating parameters, including wattage, torque, RPM, and efficiency. Review electromagnetic induction and learn its role in the operation of AC motors. Learn about variable frequency drive (VFD) systems and their ability to increase AC motor versatility and efficiency. Perform guided experiments involving AC motor control.

Introduction to Permanent Magnet DC Motors

Explore various forms of brush-type and brushless permanent magnet (PM) motors. Learn how pulse width modulation (PWM) can be implemented to control DC motor speed. Identify motor speed and position sensing devices, including encoders, resolvers, and tachometers. Investigate closed-loop control systems containing servomotors. Engage in PBL activities involving PWM motor control.

Introduction to Stepper Motors

Learn the structure and operation of unipolar and bipolar stepper motors. Investigate common stepper motor control techniques, including full-stepping, half-stepping, and micro stepping. Survey various types of ready-made stepper motor controllers. Engage in a PBL activity involving a microcontroller, interface circuitry, and a stepper motor connected to a leadscrew drive mechanism.

TRACK 4 – SOON

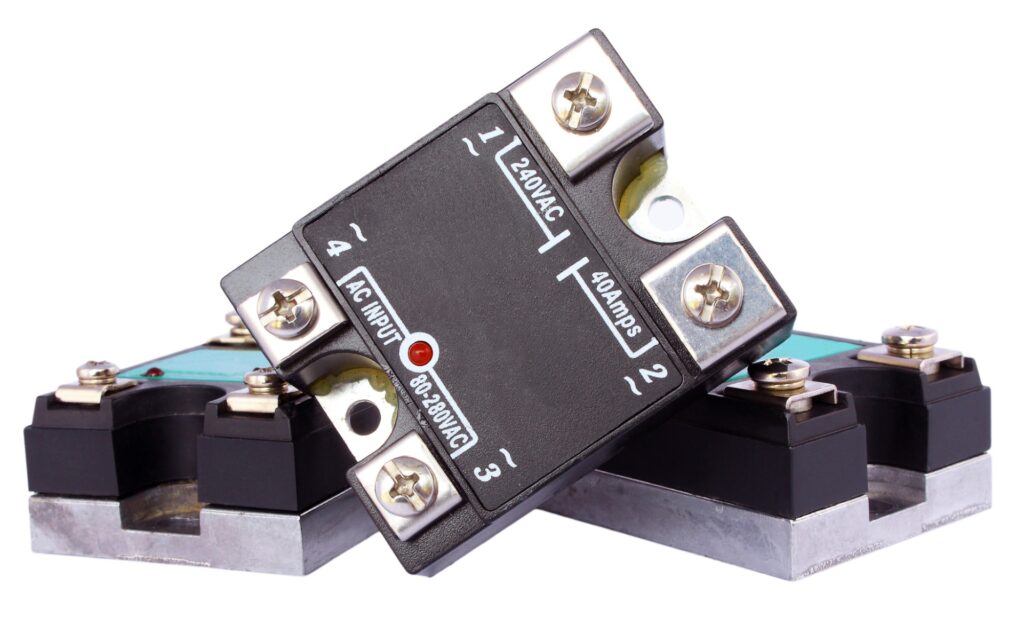

Solid-State Industrial Switching Devices

Investigate the applications of bipolar and field effect transistors as switching devices. Learn how power transistors can serve as buffer/drivers in control of electromechanical loads. Study the structure and operation of thyristors, including SCRs and TRIACS. Learn the importance of whole cycle integral control in safe commutation of high-power AC loads. Study the structure and operation of various forms of solid-state relay. Learn how they function as interface devices in microcontroller-based motor drive systems. Survey various forms of ready-made input/output modules found in industrial control systems. Become acquainted with their role in programmable logic controller (PLC) operation.

Introduction to Transistor Switching

Engage in an intense review of bipolar and field-effect transistor theory. Survey several applications of these devices as buffer/drivers in low and medium power industrial control applications. Perform a series of guided laboratory experiments demonstrating microcontroller-based load control using transistor switches and opto-isolators.

Industrial Applications of Power Transistors

Survey common industrial applications of power MOSFETs. Learn the importance of snubber networks in protecting power MOSFET circuitry. Perform guided experimentation using a power MOSFET in a PWM motor control application. Engage in a challenging PBL activity building and testing a microcontroller-based MOSFET H-bridge bidirectional DC motor controller.

Introduction to Thyristors

Learn the structure and operation of thyristors, including the SCR (silicon-control rectifier), TRIAC (triode for alternating current) and DIAC (diodes for alternating current). Survey their applications in lighting control and control of AC motors. Implement zero point and whole cycle integral switching in a PBL activity utilizing SCRs and TRIACs in DC and AC motor control.

Introduction to Solid-State Relays

Investigate the structure and operation of AC and DC solid-state relays (SSRs). Identify and explain the function of key SSR internal components, including optocouplers, thyristors, power transistors, and whole cycle integral control circuitry. Understand how SSRs can be incorporated into complex motor drive circuitry. Perform guides experiments involving AC and DC SSRs.

TRACK 5 – SOON

Industrial AC and DC Power Distribution

Review the theory and mathematical concepts necessary for understanding single-phase (1Ф) and 3Ф electrical power distribution. Understand how the 3Ф power bus can directly accessed to energize synchronous AC motors. Survey the switchgear used to control AC power distribution and provide fault detection. Learn the function of varistors, circuit breakers, emergency stop switches, and interlocks. Learn how linear and switching power supplies convert AC to DC voltage and refine it to a level suitable for powering system control circuitry. Survey various forms of DC/DC power converters and voltage regulators. Identify protective components found in electronic control circuitry, including fuses, polyswitches, and transient voltage suppressors.

Through this track, students will learn how to manage and distribute both AC and DC power efficiently in industrial environments, ensuring reliable performance and system stability.

Introduction to Industrial AC Power Sources

Master the theoretical and mathematical concepts essential to understanding 3Ф power. Learn how 3Ф power is distributed to machinery within an industrial facility. Gain familiarity with the switchgear that protects industrial equipment connected to the AC power bus. Understand the importance of isolating the AC motor power bus from the AC bus powering DC control circuitry.

Introduction to Industrial DC Power Sources

Learn the differences between linear and switching DC power sources. Recognize the strengths and weaknesses of either type of DC source. Identify the basic DC/DC power converter configurations. Understand the differences between isolated and non-isolated switching voltage regulators. Understand key voltage regulator parameters including line and load regulation.

TRACK 6 – SOON

Industrial Applications of Wireless Communication Systems

Realize how wireless communication became imperative within industry due to the rapidly rising cost of copper cabling. Learn the important guidelines established by the Federal Communications Commission (FCC) regarding unlicensed wireless communications, specifically those pertaining to frequency bands, transmission power levels, and signal duration. Understand the structure and operation of the major components of a wireless communication system, including transmitters, receivers and transceivers. Understand the terms simplex, duplex, and full duplex as they pertain to communication systems. Understand amplitude modulation (AM) and frequency modulation (FM) as they pertain to wireless communication. Identify types of modulation used in wireless communication systems. Identify and describe wireless technology standards and protocols used by industry.

Students will gain a solid understanding of wireless communication fundamentals and explore key devices and protocols used in industrial automation.

Fundamentals of Wireless Communications

Identify the essential elements of a wireless communication system. Understand the structure and operation of transceivers commonly used in wireless communications. Understand modulation and demodulation techniques commonly used in solid-state communication devices. Learn basic antenna theory as it pertains to half and quarter wave helical antennas and patch antennas.

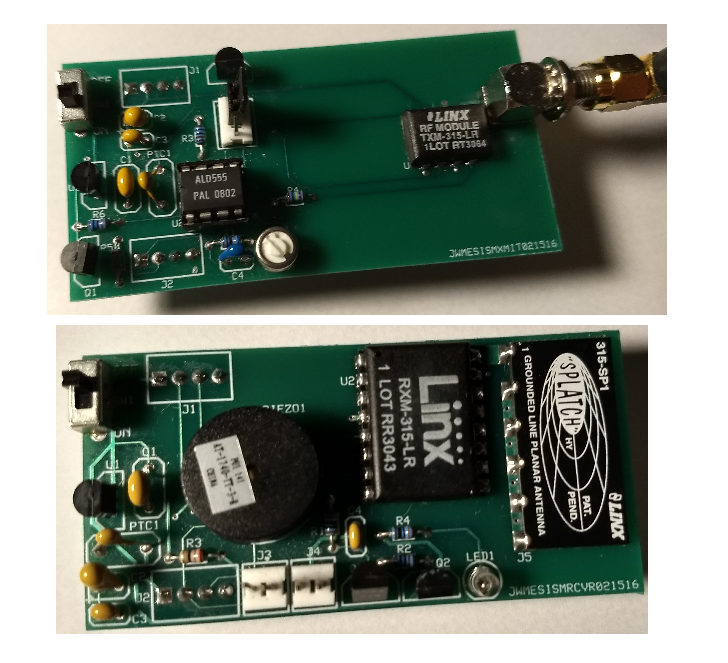

Introduction to the PRESSON Simple 315MHz Wireless Transmitter and Receiver Pair

Learn the detailed structure and operation of the Simple 315MHz Transmitter and 315MHz Receiver modules. Study the functions of the components contained on each module, referring to the datasheets for those components and the user’s guide for the transmitter/receiver pair (found in the Knowledge Base on the PRESSON website). Perform guided experimentation using the transmitter/receiver pair.

Survey of Standard Wireless Communication Protocols

Become acquainted with the protocols and wireless technology standards utilized in short range wireless communications. Investigate common unlicensed protocols, including Wi-Fi (IEEE 802.11), Bluetooth, Zigbee (IEEE 802.15.4), LoRa, and NFC. Learn the importance of providing security in wireless system design. Perform guided experiments using a pair of Silicon Labs BT122-A-V2R Bluetooth modules.